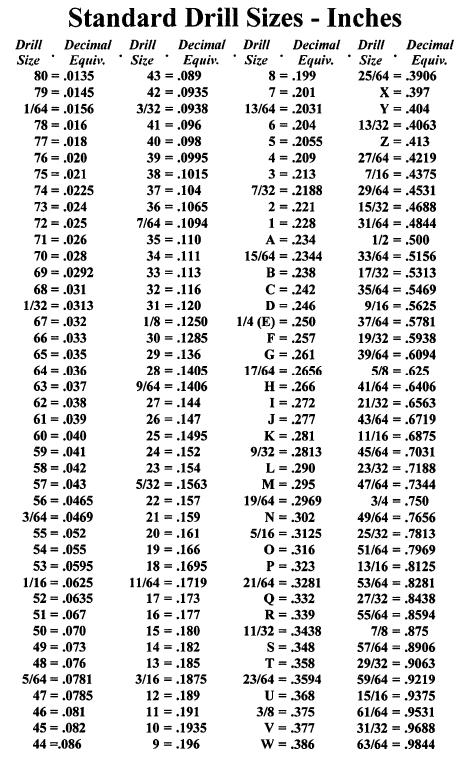

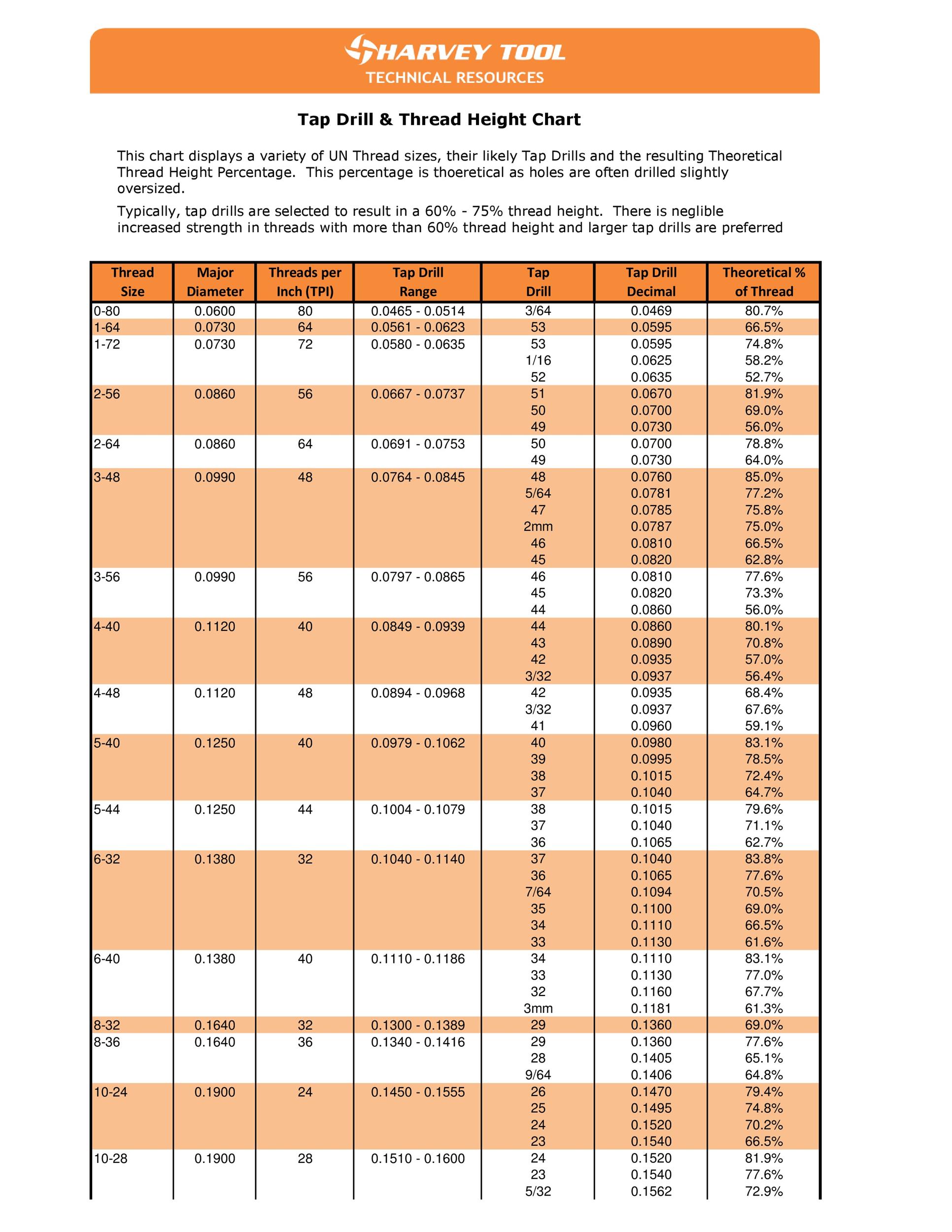

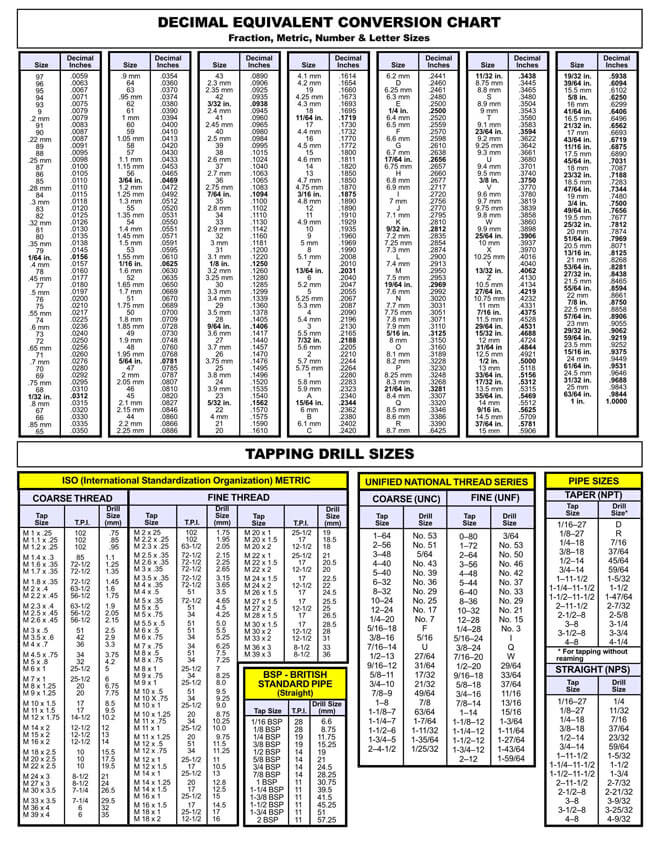

Lastly, the recommended tap drill size is provided for each standard tap size. AISI-SAE Carbon and Alloy Steel Numbering. The drill size chart contains tools up to 1.5 inches in diameter, but larger tools are also commonly used.įor each thread count, the equivalent thread pitch is provided and for metric taps, the approximate thread count is shown based on the pitch. Tap Drill Sizes (Pipe Taps) Tap Drill Sizes (Fractional) Abrasive Grading Standards. The metric system uses the thread pitch, which is the distance between threads, measured in millimeters. In the fractional and screw size systems, the thread count is used, measured in threads per inch, such as UNF threads and UNC threads. The thread spacing can be coarse or fine, will be listed after the diameter. A screw size number corresponds to a diameter which is larger for a higher screw size. Fractional sizes are listed in inches, metric sizes are listed in millimeters following the letter "M". The tap size chart is a table that lists standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. The decimal equivalents of the diameters are shown in both English and Metric units. The wire gauge and letter systems refer to tool diameters that increase as the wire gauge decreases from #107 to #1 and then continues from A to Z.

Fractional sizes are measured in inches, while metric sizes are measured in millimeters. The drill size chart is a table list standard size drill bits in several measurement systems, including fractional, metric, wire gauge number, and letter. People would need a drill size chart and tap size chart to determine the proper tap drill for a certain thread size or proper tap for an existing hole. One of the most common ways to produce the thread holes is to drill a hole of the right size with a drill bit and tap it with a tap. When manufacturing custom CNC machining parts, holes with screw threads are often required for fastening the finished part or facilitating the building. What is the Drill and Tap Size Chart and Why to Use Them?

When it comes to the selection of drill bit sizes and tap sizes, there are standard drill and tap size chart for reference. Drilling is a process of producing a hole while tapping is a technique used to cut a thread inside a hole, so the drill bit and tapping tool are often used in sequential to fabricate CNC parts with thread holes.

0 kommentar(er)

0 kommentar(er)